Polysol

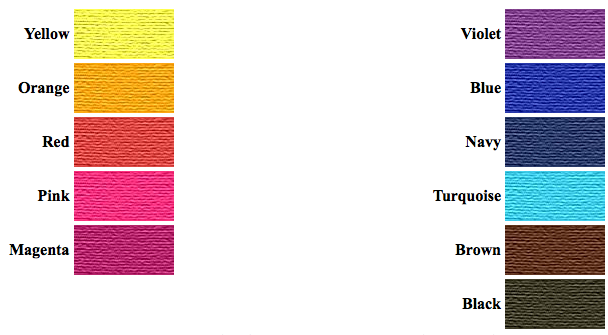

Disperse (sublostatic / transfer) dyes for transfer printing & dyeing of polyester fabric lengths. Brilliant fast colours.

Polysol dyes are easily mixed to produce colours not available as straight colours:

For example....

Polysol dye 50g $12.10 100g $23.10 500g $82.00

Polysol Carrier - assists with the uptake of dye, use only with immersion dyeing, not transfer printing

100ml $8.50 500ml $25.00 1 litre $42.50

Transfer papers - pre printed papers, 4 designs, each approx 55 x 80cm Pack of 4 $2.00

Crayola Fabric Crayons - transfer dyes in crayon form - pack of 8 colours $7.50

Polysol Transfer Kit - 10g each of 5 colours (Yellow, Magenta, Blue, Brown, & Black), DR 33 thickener,

& full instructions $35.00

Dye Instructions...

TRANSFER PRINTING

This extremely easy process for decorating fabric with brilliant colours is nonpolluting, safe, and does not require either fixing agents or rinsing. The fabric remains supple and retains its original feel. These dyes offer great flexibility of application: the design can be applied by brush using water colour technique, fine writing pen, roller, printing block, and silk screen method.

The process consists of painting the design onto paper by any method. After the paper has dried, the design is placed face down onto the fabric and then subjected to heat and pressure. The painted dye sublimates (changes from solid to vapour), under the heat and is absorbed by the fibre. The final result is very brilliant colour, fast to light and washing.

Although the colours, as they appear on the paper after it has dried, are dull and uninteresting, the colour on the fabric will be brilliant - so remember that true colour appears only after absorption into the fibre.

Every possible technique can be used to create texture variations on the fabric ... collage of preprinted paper, placing objects under the fabric, placing a leaf between fabric and preprinted paper would give a clear silhouette of the leaf, etc. We suggest the book "Colour Moves" by Linda Kemshall. It is now out of print, but well worth tracking down on eBay or Amazon.com

Polysol transfer dyes are suitable to print on synthetics such as polyester and nylon. The dyes have NO affinity for natural fibres, but mixtures containing at least 65% synthetic can be dyed - you will just get paler images. Do a test sample first to check whether your fabric can withstand the heat.

METHOD

Paste the dye with just enough boiling water to dissolve it. Then add cold water to required strength. There are no set rules as to how much water should be used, but, as a guide, 10g per 100ml of water will give full intensity & 3g per 100ml will give pastel shades. Dyes can be thickened with DR33 paste for printing or painting. Thickened dye produces sharper, clearer lines. To do this, dissolve the DR33 with a small amount of methylated spirits. Slowly add this to the dye solution, stirring all the time. Allow to stand to thicken fully. 1g DR33 per 100ml dye solution should be thick enough for most techniques. It must be remembered that every nuance of texture, however insignificant, will be faithfully reproduced during heat transfer.

Paint or print your design onto paper and allow to dry. For best results use thin non-absorbent paper with a shiny surface eg. photocopy or litho paper - not waxed paper. Colours will appear dull on paper but brighten and change during heat transfer. Do some test pieces first. The colours are fully intermixable so with a bit of practice you can create your very own colour range. You don’t have to transfer exactly what you have painted - cut it up, move it about, etc. Experiment.

To prepare for transfer, place your fabric on a bed of clean paper or a smooth towel, and tape your paper design face down onto the fabric to prevent it moving. Cover with a sheet of thin clean paper. Pre-heat your iron to 200C (approx wool setting). Irons without steam holes work best as the holes can leave polka dots in the design unless they are constantly moved, which can cause blurring. An Elna press or similiar gives the best results ! Once the iron is hot, press slowly on the design, staying in the same spot for 20-30 seconds. It is a good idea to lift a corner of the design to check if the transfer is working. Continue ironing until you are satisfied with the results. The dye is now permanently fixed to the fabric and requires no further treatment.

After printing, quite a lot of dye remains on the paper and it is possible to reprint the same design several times, the colour becoming paler with each transfer.

Transfer dyes are also available in crayon form - Crayola Fabric Crayons - pack of 8 colours for $7.00 .

DYEING POLYESTER FABRIC (& LACES ETC) WITH POLYSOL DYES

Weigh your fabric (dry)

For every 100g of fabric you will need:

a) up to 5 g of dye

b) 3ml polysol carrier (only necessary for dark/strong colours)

c) 1.5 to 2 litres of water

Wet out fabric thoroughly. Put to side.

Fill dye pot with correct amount of water.

Dissolve dye in small amount of boiling water and add to dye pot. Stir.

Dissolve carrier in small amount of hot water and add to dye pot. Stir.

Add fabric to dye pot. Stir.

Slowly bring to boil. Stirring at frequent intervals.

Turn down to simmer and maintain for 30 - 60 minutes. Stirring...

You can leave the fabric in dyepot to cool, and then rinse OR take it out of dyepot whilst still hot and rinse in hot water. DO NOT put hot polyester fabric into cold water ! Will make creases etc permanent....

Rinse well. Wash.